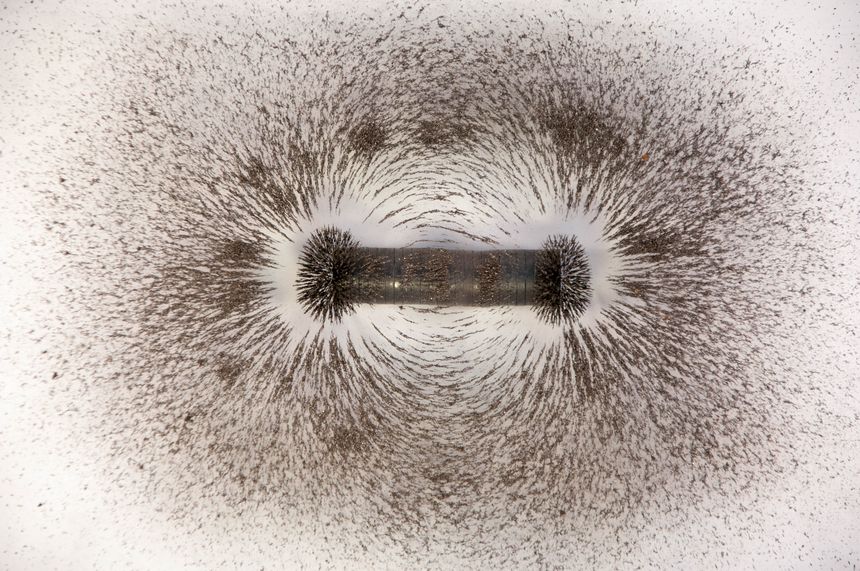

As with most processes, recycling relies heavily on machinery that is predominantly formed from ferrous metals. How then, do you process magnetic materials that will stick strongly to the surfaces of such machinery? This is a question of growing importance as decarbonisation and electrification increase demand for high-performance magnets and supplies of the rare earth elements needed to produce them are squeezed.

A team of researchers from the University of Birmingham have found a solution to this problem, using hydrogenation to ‘demagnetise’ and fragment rare earth magnets into a magnetically inert powder. They have also developed a process to reconstitute the powder into new magnets by compression and heating, using only a tenth of the energy that would be required to produce a magnet from raw materials.

For someone working in IP, it's great to see an idea that has been developed over the course of many years reach full commercial roll out and the hard work of all those involved paying off.

"[The plant is] the culmination of more than 20 years' work and this facility has been developed by 40 or 50 people" - Prof Allen Walton

/Passle/6130aaa9400fb30e400b709a/SearchServiceImages/2026-02-13-16-54-03-248-698f572b99773b214339c51d.jpg)

/Passle/6130aaa9400fb30e400b709a/SearchServiceImages/2026-02-13-12-42-47-548-698f1c477c75eb0bbb806c95.jpg)

/Passle/6130aaa9400fb30e400b709a/SearchServiceImages/2026-02-13-11-05-18-347-698f056e7c75eb0bbb7fdada.jpg)