Additive manufacturing (also known as 3D printing) has been hitting the news for several years now, but with the speed of technological development only increasing, it is becoming inevitable that this new manufacturing technique is going to have a transformational effect on all kinds of manufacturing, and, consequently on IP protection.

Additive manufacturing techniques create products by incrementally adding material layer-by-layer. In addition to polymer products, metal objects (eg pump wheels and entire jet engines), medical and dental implants, pharmaceuticals/pills, entire concrete houses, ceramics, foodstuffs and even human cells and replacement blood vessels have all been created using this technique.

The IP challenges manufacturers are likely to be facing as a result are by no means limited to those manufacturers that use the technique themselves. In fact, parties that continue to operate without keeping the opportunities and challenges of additive manufacturing in mind are likely to be disadvantaged the most.

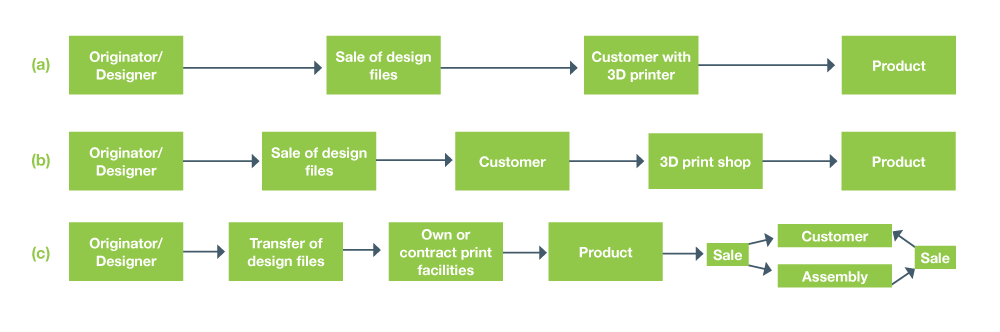

Figure 1: The 3D printing supply chain

Figure 1(a): Individual consumers print products at home on a privately owned printer

Figure 1(b): Local print shops print products for individual consumers or companies

Figure 1(c): Industrial printing centres print components/products for further assembly or sale

R&D-based industries will face the following challenges to their IP:

- Products created using additive manufacturing techniques may not be covered by patents drafted with traditional manufacturing techniques in mind.

- Additive manufacturing only requires a CAD file of the product to be manufactured and access to a suitable 3D printer, de-skilling manufacturing and creating the potential for a large number of new infringing parties to enter the market, in particular in scenarios (a) and (b) above and making policing and enforcement more difficult.

- Additive manufacturing may be less dependent on the availability of low labour costs than traditional manufacturing techniques, and so additive manufacturing can be undertaken in any location/geography. IP right holders may wish to consider if their current IP filing strategies are fit for purpose, even in scenario (c) above.

- As 3D printers can be located close to the point-of-use or -sale of a product, the number of physical products crossing international borders may decrease. Instead, electronic files may be delivered via the internet, rendering border detention less effective.

- Encryption efforts to avoid analysis by rights holders of the content of electronic files delivered via the internet are already underway, making detection of potential infringement more difficult.

- Product designs may be easily changed/tailored by manufacturers as well as by users. Traditional ways of securing design protection may need to be re-thought.

- The ubiquity of 3D scanners makes re-creating CAD files of a product very easy. This may lead to a proliferation of copied products.

Current IP law is very much suited to dealing with direct infringement. In scenario (c) mentioned above, a large number of infringing products are manufactured, sold, imported etc. by a single party. It is likely that patent law will continue to be a suitable means for stopping this kind of infringement.

In scenarios (a) and (b), the potentially high number of printers/parties manufacturing products will likely make it impractical to pursue a significant number of printers. If lessons learnt by the music industry in dealing with illegal downloads are anything to go by, this means pursuing the parties providing the printable files or internet service providers enabling the distribution of these files is likely to be a preferred option. European patent laws do provide for sanctions against indirect infringement in cases where a party provides an “essential element of the invention”. Under UK patent law, however, it is necessary that the party providing the essential means knows (or if it is obvious to a reasonable person in the circumstances) that these essential means are suitable for and intended to put the invention into effect.

It seems unlikely that a CAD file would be considered a means essential for manufacturing a protected product. This is because the CAD file does not facilitate the direct printing of the product (it needs to go through several conversion steps first). Moreover, the CAD file may well be argued to have other non-infringing uses, for example in territories that are not covered by patents.

One attempt to increase the likelihood of being able to assert contributory infringement in respect of the CAD file could take the form of a claim that comprises the creation of the CAD file as one of its steps. Inevitably a claim of this nature must be present alongside other/broader claims for the product or methods of manufacturing the product. Claims for the product or for its manufacture may ideally be substituted with claims for a computer program that, when executed by a 3D printer, performs the product manufacturing process and for a computer program that, when executed by a 3D printer, creates a novel and inventive product. Most useful would of course be a claim that simply claims a computer model of a new product.

Claims of the above proposed nature have not yet been tested. However, given the fact that it is not possible to add claims of this nature after the filing of a patent application in Europe, applicants would be well advised to include even untested claims, or corresponding statements of invention, in their originally filed patent applications.

IP rights of manufacturers using traditional manufacturing techniques may also suffer inadvertently through claim drafting that does not take the opportunities provided by additive manufacturing (irrespective of whether or not the inventor himself or herself plans to use this new technique at all) into account.

Imagine, for example, a product comprising two interlinking components. Traditionally, these components would be manufactured separately and then assembled in an interlinked fashion. Patent protection covering this product may reflect this sequence of manufacturing steps. However, if the interlinking components are 3D-printed simultaneously so that they interlink from the start, then a traditionally worded patent may well not cover the 3D-printed arrangement.

It is not only in the patents field that additive manufacturing is likely to challenge best practice in the IP industry. With CAD software making it easier to modify designs electronically, designers may wish to focus design registrations on those features of the product that are believed to make the product attractive to buyers but to omit those features that are deemed of lesser importance to the appearance of the product. In so doing, emphasis is placed on the product features that are less likely to be modified by a consumer trying to individualise a product prior to printing. In addition designers may wish to pursue multiple design registrations with varying level of detail.

Whilst registered design rights are regrettably unlikely to be useful in stopping the dissemination of CAD files for printing, unregistered UK design right does cover design documents and may as such provide a useful tool for stopping the dissemination of designs in electronic format.

Changing your business model to anticipate electronic files being sold for home-printing or infringement threats coming through this channel will also require thought about trade mark strategy. Trade marks may, for example, be registered to cover print files as well as custom manufacturing services and trade mark owners may wish to include their marks on products in ways that are picked up by 3D scanners, so that display of a rendered image of the printable file online automatically constitutes trade mark infringement.

It seems clear that the changes to the manufacturing industries have only just begun. Without inventors providing knowledge of a range of manufacturing techniques (including additive manufacturing) that may be used to create their product – and there will likely be many as the use of this technique grows – only IP Attorneys with a very good grasp of the possibilities it provides can assist in avoiding inadvertent gaps in protection.

/Passle/6130aaa9400fb30e400b709a/SearchServiceImages/2025-06-26-20-40-16-891-685db030164d0ed2766d379d.jpg)

/Passle/6130aaa9400fb30e400b709a/SearchServiceImages/2025-06-25-11-12-24-932-685bd998940174cbf0e60fba.jpg)

/Passle/6130aaa9400fb30e400b709a/MediaLibrary/Images/2025-06-24-17-47-11-584-685ae49f940174cbf0e437a2.png)